Select your Industry & Application

Select your Industry & Application

- Renewables

- Transmission

- Storage

- Utility

- Industrial

- Power Gen

- RNG Equipment

- Hydrogen & Gas Blending Equipment

- Utility Back-Up Equipment

RNG Equipment

Aether DBS offers various RNG and Biogas Skid packages for various applications and industries.

Landfill Gas – dewatering, filtration and compression

Skidded equipment for preparing raw landfill gas for combustion in reciprocating engines and other power equipment. Moisture knockout, coalescing filters; screw, rotary lobe, sliding vane and other compression equipment; and gas cooling systems integrated together on structural skids.

Biogas Conditioning

Biogas requires dewatering, filtration, compression and removal of certain contaminants to be usable. Depending upon the end use, technologies such as coalescing filtration, particulate filtration, Pressure Swing Adsorption for CO2 and hydrogen sulfide removal, siloxane removal, molecular sieve membranes, glycol dehydration, and others can be incorporated. End uses include power generation, pipeline quality gas, and compression for vehicle fuel.

Digester Gas – dewatering, filtration and compression

- Municipal WWTP: Sludge digester gas conditioning and compression system – We have specific experience blending with natural gas for internal plant usage and utilizing for Combined Cycle power plants

- Food Waste: Digester gas conditioning and compression – We have specific experience blending with natural gas for microturbine power generation

- Agricultural Waste: Cow and Poultry Manure digester gas conditioning and blending for in-plant power generation and pipeline quality gas.

Hydrogen & Gas Blending Equipment

Many industrial, municipal, and agricultural facilities generate a source of gas as a byproduct of their operations. The classic problem for these Customers is that the gas generation is variable – both in quantity and in quality, and therefore unsuitable for use as a fuel gas by itself. However, by blending this byproduct gas with another gas of known quantity and quality, these Customers can take advantage of using their own gas to offset utility bills, and save emissions and waste. Aether gas blenders are used for this primary purpose – allowing Customers to utilize their own gas without flaring or venting, and improving their carbon footprint in the process.

Hydrogen Blending – The future of gas usage will include hydrogen. Many Customers are now exploring how to use this abundant gas, and in the transition period, to blend H2 with CH4, to reduce their carbon footprint. The Aether AFC blender, designed with materials of construction compatible with Hydrogen, is the solution.

Hydrogen Blending – The future of gas usage will include hydrogen. Many Customers are now exploring how to use this abundant gas, and in the transition period, to blend H2 with CH4, to reduce their carbon footprint. The Aether AFC blender, designed with materials of construction compatible with Hydrogen, is the solution.

Solutions Built & Delivered

Hydrogen Blending with a University Calibration Laboratory…..

Hydrogen Blending at a Pennsylvania LDC testing facility…..

Hydrogen Blending with a California Refinery…..

Hydrogen Blending in a Maryland Distribution System….

Refinery Gas with NG to limit flaring – refineries have multiple sources of byproduct gases – some of them rich in BTU content and some of them too lean to utilize alone. Flaring and/or venting have been traditionally used to get rid of these gases. Now, by blending these with a pipeline-quality natural gas, reduced flaring and increased emissions compliance can be realized. Aether AFC-powered Recover blend systems can be used for these Customers.

NG and RNG Blending – Renewable natural gas, typically sourced from animal or agricultural waste, can be blended with pipeline quality natural gas in order to fully utilize a waste resource, reduce emissions, and reduce carbon footprint. Gas from digesters, covered lagoons, and waste pits can all be blended with high quality natural gas using our AFC blenders.

Off Spec Gas Blending for Fuel Gas – many Customers facility processes generate gases that are high in sulfur or moisture or other contaminants, that alone cannot be reliably used for fuel a combustion unit. However, blend that gas at controlled rates, and the gas may be able to be used for beneficial purposes. Sagebrush can evaluate individual cases and simulations, using Aether blender technology, to evaluate gas blends and usability.

Utility Backup Equipment

Synthetic Natural Gas (SNG) – Propane Air Mixing System (read more)

Backup for Wind & Solar – Aether Fuel Gas equipment is essential for facilities that back-up renewable wind and solar power generation. Capacity payments and reliability concerns with the intermittent power generated from wind farms and solar fields require reliable “turn on at any time” power generation. The reliable, clean fuel choice for those back-up power systems is natural gas, and Aether fuel gas conditioning systems, which control the temperature, pressure, flow, and quality of the natural gas, are used to make those renewable sites more reliable and functional at critical times.

Peak Shaving – Most utility Customers have interruptible rates for their large customers. This simply means the utilities can turn off or turn down the natural gas supply to those customers during periods of peak demand. In order to “peak shave” these high demand cycles, the utilities utilize Aether SNG systems to supplement their operations. In other cases, the large industrial Customers themselves rely on Aether SNG systems during those peaks to provide a supplemental gas supply that automatically takes over for the incoming gas supply.

Vent Gas Scrubber – Many utilities, and local distribution companies in particular, have valves and regulators that are pneumatically controlled with natural gas from the pipelines themselves. This is effective, but the gas vents to the atmosphere, causing fugitive emissions. Aether’s vent gas scrubber canisters provide an easy, fast retrofit for these systems, so that the venting gas is scrubbed through carbon or other treatment media prior to discharge, reducing emissions and carbon footprint.

Actuation Air Systems – Another option for gas venting is to permanently retrofit the gas-powered pneumatic actuators with an Aether compressed air system, whereby the actuators will run on compressed air supply, completely eliminating the fugitive gas emissions from the regulators or control valves. Aether packages the compressor, instruments, and controls on a skid, ready to plug-and-play at the valve site, permanently reducing the carbon footprint. See our instrument air packages here (Read more).

- Gas & Liquid Measurement

- Regulation & Flow Control

- Traps & Main Line

- Heaters

- Gas Conditioning

- Measurement & Control Enclosures

Gas and Liquid Measurement

Sagebrush provides turnkey design and fabrication of measurement systems, skid mounted or otherwise, required for custody transfers. These systems are assembled and tested for gas or liquid measurement.

Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of AGA, API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple meter run skids

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Noise attenuation

* Header systems

* Flow conditioners

* GC’s, Flow Computers, and PLC’s

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted measurement systems.

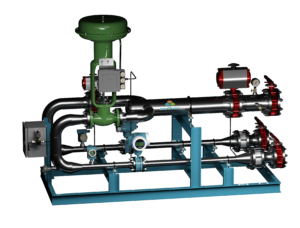

Regulation and Flow Control

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Traps and Main Line

Sagebrush provides fabricated launchers and receivers or “traps,” for pipeline pigging. Our traps can be equipped for automated or manual loading and launching of pigs. Traps can be skid mounted or shipped as complete stand-alone units. Each prefab option reduces installation time.

To reduce the need for field labor, in sometimes compromising field conditions, Sagebrush provides fabricated Main Line Valve settings (MLV’s) and Valve Value Add services. In each case, special attention to prefab preparation and in-house NDE testing ensures the integrity of valve seats and seals is maintained.

As with every Sagebrush order, strict adherence to customer specifications and applicable codes and standards is paramount and ensures our product meets your expectations.

Fabrication services included or offered for traps and/or MLV’s:

* Engineering & design assistance

* Total turnkey – materials & labor

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Valve “pup” and additional pipe extensions

* Quick open closures

* Valve stem extensions

* Riser and bypass fabrication

* Full block, blowdown, & piping system assemblies

* Below & above ground coating systems to prevent corrosion

* Sagebrush “Pig Trip” pig signaler(s)

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated launcher/receiver systems, mainline valve settings, and valve value add service

Heaters

Aether DBS offers Gas, Electric and Steam Heaters for various applications and industries.

Gas Conditioning

Aether DBS offers various Gas Conditioning Skid packages for various applications and industries.

Enclosures and Modular Structures

Aether Sagebrush offers custom designed enclosures and canopies for equipment and personnel protection from the elements. Aether Sagebrush structures include PE stamped drawings registered in the final destination state as well as compliance to all applicable state label requirements

When designing our structures, Aether Sagebrush complies with the latest IBC codes. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Available applications:

* Piping skids (meter, control, fuel gas, etc.)

* Heater Maintenance Enclosure

* Gas Chromatograph (GC) and/or Electronic Flow Measurement (EFM)

* Remote Terminal Unit (RTU)

* Motor Control Center (MCC)

* Low-voltage, switchgear

* Complete system installation inside a 20- or 40-foot ISO container

Options include but are not limited to:

* Rigid-Frame design

* 1-room or multiple room options including vapor barrier walls when required by code for electrical classification requirements

* Single-Mod or Split-Mod designs to accommodate wide loads

* Fire-rated plywood in walls to support installation of indoor equipment with ease

* Thermal or Acoustic insulation available as required

* Custom exterior designs and colors available

* 20 yr. warranty on all baked-on enamel coatings (conditions apply)

* Hinged or Roll-up doors available for equipment access

* Hinged doors come with Roton continuous hinge design eliminating the need to adjust doors to fit the frame once on site

* Gable or Single-Sloped roof designs available with drop ceilings if needed.

* HVAC, Exhaust, adjustable or fixed louvers available for climate control and requisite air changes to meet electrical classification requirements

* Designed for C1D1, C1D2, or General Purpose as required by NEC

* Gas detection, isolation, and alarm available

* Available Canopy Options: Removeable, canopy skirt, field or shop erected, customer colors

* Complete integration of convenience packages including junction/interface boxes, lights, switches, receptacles, wall penetrations, and conduit/raceway installation

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Aether Sagebrush the energy industry’s preferred choice for skids with Modular Structure requirements.

- Gas & Liquid Measurement

- Regulation & Flow Control

- Filtration

- Heaters

- Gas Conditioning

Gas and Liquid Measurement

Sagebrush provides turnkey design and fabrication of measurement systems, skid mounted or otherwise, required for custody transfers. These systems are assembled and tested for gas or liquid measurement.

Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of AGA, API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple meter run skids

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Noise attenuation

* Header systems

* Flow conditioners

* GC’s, Flow Computers, and PLC’s

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted measurement systems.

Regulation and Flow Control

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Filtration

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Heaters

Aether DBS offers Gas, Electric and Steam Heaters for various applications and industries.

Gas Conditioning

Aether DBS offers various Gas Conditioning Skid packages for various applications and industries.

- Gas & Liquid Measurement

- Regulation & Flow Control

- Traps & Main Line

- Heaters

- Gas Conditioning

- Synthetic Natural Gas

- Measurement & Control Enclosures

Gas and Liquid Measurement

Sagebrush provides turnkey design and fabrication of measurement systems, skid mounted or otherwise, required for custody transfers. These systems are assembled and tested for gas or liquid measurement.

Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of AGA, API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple meter run skids

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Noise attenuation

* Header systems

* Flow conditioners

* GC’s, Flow Computers, and PLC’s

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted measurement systems.

Regulation and Flow Control

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Traps and Main Line

Sagebrush provides fabricated launchers and receivers or “traps,” for pipeline pigging. Our traps can be equipped for automated or manual loading and launching of pigs. Traps can be skid mounted or shipped as complete stand-alone units. Each prefab option reduces installation time.

To reduce the need for field labor, in sometimes compromising field conditions, Sagebrush provides fabricated Main Line Valve settings (MLV’s) and Valve Value Add services. In each case, special attention to prefab preparation and in-house NDE testing ensures the integrity of valve seats and seals is maintained.

As with every Sagebrush order, strict adherence to customer specifications and applicable codes and standards is paramount and ensures our product meets your expectations.

Fabrication services included or offered for traps and/or MLV’s:

* Engineering & design assistance

* Total turnkey – materials & labor

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Valve “pup” and additional pipe extensions

* Quick open closures

* Valve stem extensions

* Riser and bypass fabrication

* Full block, blowdown, & piping system assemblies

* Below & above ground coating systems to prevent corrosion

* Sagebrush “Pig Trip” pig signaler(s)

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated launcher/receiver systems, mainline valve settings, and valve value add service

Heaters

Aether DBS offers Gas, Electric and Steam Heaters for various applications and industries.

Gas Conditioning

Aether DBS offers various Gas Conditioning Skid packages for various applications and industries.

Synthetic Natural Gas (SNG)

SNG (Synthetic Natural Gas) is a mixture of LPG (Liquified Petroleum Gas) and air that simulates natural gas, providing an alternative energy solution.

SNG can act as a direct replacement for natural gas, or can be blended with natural gas to overcome the shortcomings and costs of natural gas.

SNG works in all fuel applications, and there are no pressure changes or burner replacements or adjustments needed.

SNG Applications:

As a backup for intermittent or unreliable natural gas service

As a substitute for natural gas in areas where natural gas is not available

Bridging – natural gas isn’t currently offered, but will come online in the future

For peak shaving – to control the cost of natural gas during peak demand times

Aether dbs has designed, manufactured, and commissioned the world’s largest SNG natural gas augmentation systems.

A complete SNG system includes an LPG storage system, LPG pump sets, vaporizers, an air source, and a blending system.

We customize the vaporizers and blenders in each of our SNG systems to fit our clients’ needs.

We can provide gas-fired, steam, electric, or recirculating water vaporizers to fit the existing heat supply.

We offer a venturi blending system for applications up to 30psi, and Active Flow Control blending systems for greater pressure and control needs.

Aether DBS’ SNG technologies are cost effective, quick to implement, and proven. Let us be part of the team to solve your natural gas problems.

Enclosures and Modular Structures

Aether Sagebrush offers custom designed enclosures and canopies for equipment and personnel protection from the elements. Aether Sagebrush structures include PE stamped drawings registered in the final destination state as well as compliance to all applicable state label requirements

When designing our structures, Aether Sagebrush complies with the latest IBC codes. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Available applications:

* Piping skids (meter, control, fuel gas, etc.)

* Heater Maintenance Enclosure

* Gas Chromatograph (GC) and/or Electronic Flow Measurement (EFM)

* Remote Terminal Unit (RTU)

* Motor Control Center (MCC)

* Low-voltage, switchgear

* Complete system installation inside a 20- or 40-foot ISO container

Options include but are not limited to:

* Rigid-Frame design

* 1-room or multiple room options including vapor barrier walls when required by code for electrical classification requirements

* Single-Mod or Split-Mod designs to accommodate wide loads

* Fire-rated plywood in walls to support installation of indoor equipment with ease

* Thermal or Acoustic insulation available as required

* Custom exterior designs and colors available

* 20 yr. warranty on all baked-on enamel coatings (conditions apply)

* Hinged or Roll-up doors available for equipment access

* Hinged doors come with Roton continuous hinge design eliminating the need to adjust doors to fit the frame once on site

* Gable or Single-Sloped roof designs available with drop ceilings if needed.

* HVAC, Exhaust, adjustable or fixed louvers available for climate control and requisite air changes to meet electrical classification requirements

* Designed for C1D1, C1D2, or General Purpose as required by NEC

* Gas detection, isolation, and alarm available

* Available Canopy Options: Removeable, canopy skirt, field or shop erected, customer colors

* Complete integration of convenience packages including junction/interface boxes, lights, switches, receptacles, wall penetrations, and conduit/raceway installation

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Aether Sagebrush the energy industry’s preferred choice for skids with Modular Structure requirements.

- Gas & Liquid Measurement

- Regulation & Flow Control

- Heaters

- Gas Conditioning

- Synthetic Natural Gas

- Ammonia DeNOx

- Measurement & Control Enclosures

Gas and Liquid Measurement

Sagebrush provides turnkey design and fabrication of measurement systems, skid mounted or otherwise, required for custody transfers. These systems are assembled and tested for gas or liquid measurement.

Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of AGA, API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple meter run skids

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Noise attenuation

* Header systems

* Flow conditioners

* GC’s, Flow Computers, and PLC’s

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted measurement systems.

Regulation and Flow Control

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Heaters

Aether DBS offers Gas, Electric and Steam Heaters for various applications and industries.

Gas Conditioning

Aether DBS offers various Gas Conditioning Skid packages for various applications and industries.

Synthetic Natural Gas (SNG)

SNG (Synthetic Natural Gas) is a mixture of LPG (Liquified Petroleum Gas) and air that simulates natural gas, providing an alternative energy solution.

SNG can act as a direct replacement for natural gas, or can be blended with natural gas to overcome the shortcomings and costs of natural gas.

SNG works in all fuel applications, and there are no pressure changes or burner replacements or adjustments needed.

SNG Applications:

As a backup for intermittent or unreliable natural gas service

As a substitute for natural gas in areas where natural gas is not available

Bridging – natural gas isn’t currently offered, but will come online in the future

For peak shaving – to control the cost of natural gas during peak demand times

Aether dbs has designed, manufactured, and commissioned the world’s largest SNG natural gas augmentation systems.

A complete SNG system includes an LPG storage system, LPG pump sets, vaporizers, an air source, and a blending system.

We customize the vaporizers and blenders in each of our SNG systems to fit our clients’ needs.

We can provide gas-fired, steam, electric, or recirculating water vaporizers to fit the existing heat supply.

We offer a venturi blending system for applications up to 30psi, and Active Flow Control blending systems for greater pressure and control needs.

Aether DBS’ SNG technologies are cost effective, quick to implement, and proven. Let us be part of the team to solve your natural gas problems.

Ammonia DeNOx

Aether dbs offers a variety of Ammonia Off Loading, Storage, Forwarding and Vaporization Solutions for SCR and other industrial applications in both 19% and 29% Aqueous Ammonia and Anhydrous.

Enclosures and Modular Structures

Aether Sagebrush offers custom designed enclosures and canopies for equipment and personnel protection from the elements. Aether Sagebrush structures include PE stamped drawings registered in the final destination state as well as compliance to all applicable state label requirements

When designing our structures, Aether Sagebrush complies with the latest IBC codes. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Available applications:

* Piping skids (meter, control, fuel gas, etc.)

* Heater Maintenance Enclosure

* Gas Chromatograph (GC) and/or Electronic Flow Measurement (EFM)

* Remote Terminal Unit (RTU)

* Motor Control Center (MCC)

* Low-voltage, switchgear

* Complete system installation inside a 20- or 40-foot ISO container

Options include but are not limited to:

* Rigid-Frame design

* 1-room or multiple room options including vapor barrier walls when required by code for electrical classification requirements

* Single-Mod or Split-Mod designs to accommodate wide loads

* Fire-rated plywood in walls to support installation of indoor equipment with ease

* Thermal or Acoustic insulation available as required

* Custom exterior designs and colors available

* 20 yr. warranty on all baked-on enamel coatings (conditions apply)

* Hinged or Roll-up doors available for equipment access

* Hinged doors come with Roton continuous hinge design eliminating the need to adjust doors to fit the frame once on site

* Gable or Single-Sloped roof designs available with drop ceilings if needed.

* HVAC, Exhaust, adjustable or fixed louvers available for climate control and requisite air changes to meet electrical classification requirements

* Designed for C1D1, C1D2, or General Purpose as required by NEC

* Gas detection, isolation, and alarm available

* Available Canopy Options: Removeable, canopy skirt, field or shop erected, customer colors

* Complete integration of convenience packages including junction/interface boxes, lights, switches, receptacles, wall penetrations, and conduit/raceway installation

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Aether Sagebrush the energy industry’s preferred choice for skids with Modular Structure requirements.

- Gas & Liquid Measurement

- Regulation & Flow Control

- Filtration

- Heaters

- Gas Conditioning

- Ammonia DeNOx

- Measurement & Control Enclosures

Gas and Liquid Measurement

Sagebrush provides turnkey design and fabrication of measurement systems, skid mounted or otherwise, required for custody transfers. These systems are assembled and tested for gas or liquid measurement.

Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of AGA, API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple meter run skids

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Noise attenuation

* Header systems

* Flow conditioners

* GC’s, Flow Computers, and PLC’s

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted measurement systems.

Regulation and Flow Control

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Filtration

Sagebrush provides skid mounted regulator and flow control systems to accommodate customer, site, and product specific design requirements and control philosophies, as applicable, for all sectors of the oil and gas, pipeline, power generation, and industrial markets. Sagebrush will help in determining appropriate sizing, modeling specific cases, and evaluating various configurations including worker-monitor, fail-open or fail-closed, full flow or redundant, Over-Pressure Protection, and other critical parameters.

When fabricating regulator skids, Sagebrush documents compliance with interstate gas pipeline DOT regulations, the applicable standards of API, ASME, ANSI, ASTM, and customer specifications. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Fabrication services included or offered:

* Engineering & design assistance

* Single or multiple regulator skids

* Start-up lines and bypass piping

* Document controls for detailed and timely delivery of data books

* In-house instrumentation & electrical assembly

* In-house NDE – radiography & hydrotesting

* Full Factory Acceptance Testing

* Aftermarket Services

Options include but are not limited to:

* Regulating and Control Valve options

* Over-Pressure Protection

* Gas Blending

* Valve Switching

* Noise attenuation

* Header systems

* Mounted panel systems

* Sagebrush enclosures – complete skid or partial skid

* Sagebrush canopy coverings

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Sagebrush the energy industry’s preferred choice for prefabricated gas or liquid skid mounted regulation systems for pressure control.

Heaters

Aether DBS offers Gas, Electric and Steam Heaters for various applications and industries.

Gas Conditioning

Aether DBS offers various Gas Conditioning Skid packages for various applications and industries.

Ammonia DeNOx

Aether dbs offers a variety of Ammonia Off Loading, Storage, Forwarding and Vaporization Solutions for SCR and other industrial applications in both 19% and 29% Aqueous Ammonia and Anhydrous.

Enclosures and Modular Structures

Aether Sagebrush offers custom designed enclosures and canopies for equipment and personnel protection from the elements. Aether Sagebrush structures include PE stamped drawings registered in the final destination state as well as compliance to all applicable state label requirements

When designing our structures, Aether Sagebrush complies with the latest IBC codes. Our ISO 9001:2018 Certification and associated Quality Management System, Individual Inspection and Test Plans, ensure your requirements for materials, weld procedures, welder certifications, NDE, and applicable “hold points” for company or third-party inspections, are met.

Available applications:

* Piping skids (meter, control, fuel gas, etc.)

* Heater Maintenance Enclosure

* Gas Chromatograph (GC) and/or Electronic Flow Measurement (EFM)

* Remote Terminal Unit (RTU)

* Motor Control Center (MCC)

* Low-voltage, switchgear

* Complete system installation inside a 20- or 40-foot ISO container

Options include but are not limited to:

* Rigid-Frame design

* 1-room or multiple room options including vapor barrier walls when required by code for electrical classification requirements

* Single-Mod or Split-Mod designs to accommodate wide loads

* Fire-rated plywood in walls to support installation of indoor equipment with ease

* Thermal or Acoustic insulation available as required

* Custom exterior designs and colors available

* 20 yr. warranty on all baked-on enamel coatings (conditions apply)

* Hinged or Roll-up doors available for equipment access

* Hinged doors come with Roton continuous hinge design eliminating the need to adjust doors to fit the frame once on site

* Gable or Single-Sloped roof designs available with drop ceilings if needed.

* HVAC, Exhaust, adjustable or fixed louvers available for climate control and requisite air changes to meet electrical classification requirements

* Designed for C1D1, C1D2, or General Purpose as required by NEC

* Gas detection, isolation, and alarm available

* Available Canopy Options: Removeable, canopy skirt, field or shop erected, customer colors

* Complete integration of convenience packages including junction/interface boxes, lights, switches, receptacles, wall penetrations, and conduit/raceway installation

Years of experience with acute focus on quality, customized design expertise, and customer satisfaction, makes Aether Sagebrush the energy industry’s preferred choice for skids with Modular Structure requirements.

Landfill Gas – dewatering, filtration and compression

Biogas Conditioning

Digester Gas – dewatering, filtration and compression

Municipal WWTP

Food Waste

Agricultural Waste

Hydrogen & Gas Blending Equipment:

Refinery Gas with NG to limit flaring

Hydrogen Blending

NG and RNG Blending

Off Spec Gas Blending for Fuel Gas

Synthetic Natural Gas (SNG) – Propane Air Mixing System

Backup for Wind & Solar

Peak Shaving

Vent Gas Scrubber

Actuation Air Systems

Demister GAS-TRAP DM Series

Flare Stack SURE-LITE F Series

Storage Forwarding

TTU Stations

Aqua-Pak Pump Sets

Storage Tank

Stabilizer LPG Pump Packages

Vaporization

Water Bath Gas Fired

THERMO-FLOTM TF (ELECTRIC)

STEAM FLO

Blending

Venturi

AFC Blenders

SNG Package Systems

AQUA-AIRE™AA SERIES

AQUA-BLEND® AB SERIES

PLC Programmable Logic Controller

UTILI-PAK™ SYSTEM

AQUA-PAK™ SNG MODULE

Sagebrush will provide factory-trained technicians and experienced engineers to assist you in the start-up and commissioning of your Sagebrush equipment and systems.

Sagebrush provides more than just start-up operations for equipment and flow control technologies. We offer a wide range of spare parts and kits to ensure your equipment operates smoothly.

When you have a component failure, or the useful life of an expendable or replaceable part is reached, contact Sagebrush for your replacement parts

In addition to providing equipment and products for our Clients, we can support on-site installation with turnkey installs and/or installation oversight. As the manufacturer and fabricator, we know what the critical installation parameters are, that ensure a successful installation.

At Sagebrush, our engineers and field service specialists offer a comprehensive range of services to support your project needs. From equipment start-up to training and long-term maintenance, we’re committed to sustaining the life of your equipment

Our PSP Program is designed to give you years of trouble-free operation and extend the life of your Aether or Sagebrush equipment. Our factory trained technicians will provide ongoing preventative maintenance services, as well as routine mechanical and electrical inspections, and make recommendations for replacement parts or adjustments.

Standard warranty is 12 months from start-up or 18 months from shipment. Warranties of extended duration are available. Extended warranty coverage and pricing are dependent on the duration requested and the complexity of the system(s). Enrollment in Aether DBS’ PSP Program qualifies our customers for initial extended warranty coverage.

Sagebrush operates as a Limited Liability Company, and now offers the entire Aether DBS product line. The two companies merged in 2019, and under common closely-held ownership, offer a broad range of standard and custom-engineered products, in a broad market to a diverse Customer base, with world-class capabilities in design and production.

“Sagebrush delivers the best value to our Customers by providing practical, high-quality, engineered modular systems for transmission, utility and industrial infrastructure.”

Sagebrush has full production capabilities, including material sizing, rolling, fit-up, welding, assembly, electrical, I&C, NDE, NDT, QC, FAT. Three fabrication facilities with over 156,000 SF of covered, ventilated work space.

AGA 3 (Orifice)

AGA 7 (Turbine)

AGA 9 (Ultrasonic)

AGA 11 (Coriolis)

ANSI B31.1

ANSI B31.3

ANSI B31.4

ANSI B31.8

API 1104

Sagebrush equipment is sold directly. Contact us for a quote. Aether DBS products are sold through the following Representative Network: